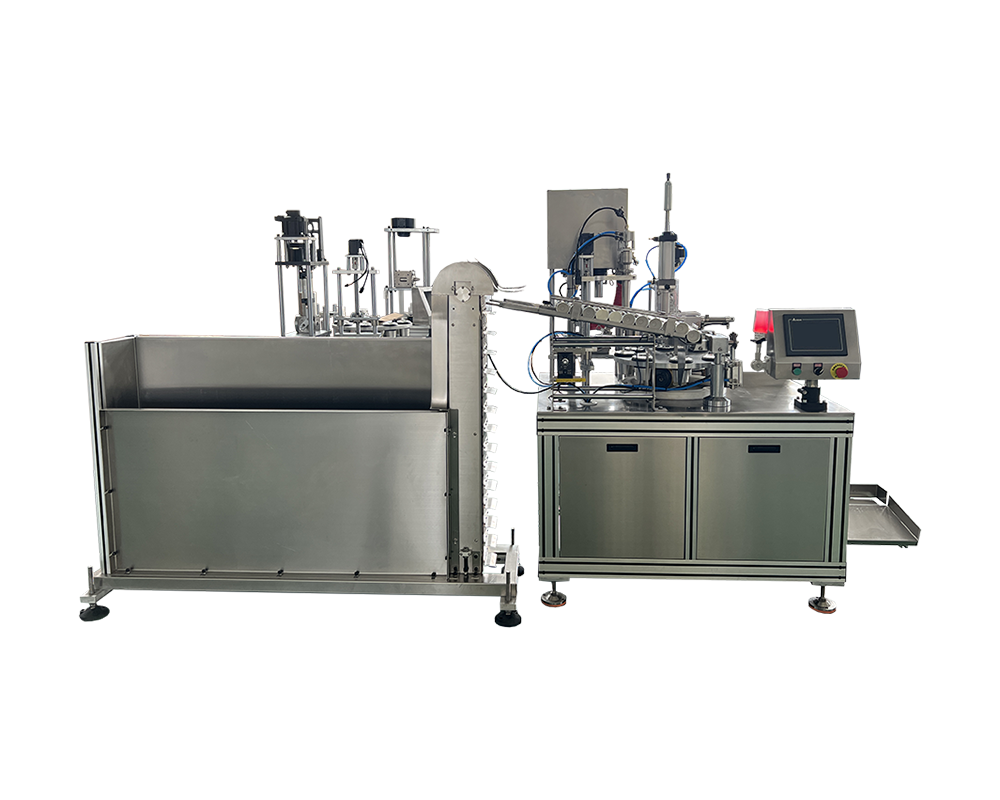

FAG Fully automatic double-head vertical tube filling machine

Product Introduction

FAG Automatic quantitative filling machine is developed by our company based on the absorption of foreign advanced technology,aiming to improve filling efficiency and accuracy.It is mainly composed of bottle unscrambler,touch screen,cylinder,servo motor,etc.It is widely used in chemical,pharmaceutical and food industries, suitable for filling various plastic bottles with various pastes,greases,sealants,glass glue,etc.

Our team consists of highly motivated and skilled specialists who know how to deal with any issue that you may come across. This creates a basis for lasting relationships with our clients built on trust and mutual understanding.

We are devoted to creating unique and innovative solutions along with the high-quality supporting services. Our team consists of highly motivated and skilled specialists who know how to deal with any issue that you may come across. This creates a basis for lasting relationships with our clients built on trust and mutual understanding.

Product Performance

Automatic control, users only need to manually add bottles and bottom caps, the equipment automatically supplies bottles/automatically quantitatively fills, automatically covers/automatically presses caps/automatically unloads materials, greatly improving production efficiency.

The whole machine adopts PLC controller and touch screen, strict precision control and processing technology of various transmission parts, the equipment is stable and responsive.

Volumetric metering cylinder is adopted, and servo motor controls quantitative. The filling metering accuracy is high (error 0.5%), and the metering parameters are adjusted by touching the screen.

Material filtration function, standard filtration device.

The whole machine is divided into three parts: bottle machine --Main filling and capping machine--capping machine

Technical Parameters

Type |

FAG 300 |

Power Supply |

380V/50HZ |

Air Supply |

≮0.5MPa |

Air Consume |

<0.3m 3 /min |

Filling Volume |

MAX 310ml (can be adjusted) |

Volume Precision |

≤±0.5℅ |

Productivity |

15~35pcs/min |

Tube Diameters |

Customized |

Dimensions(L×W×H) |

3700×950×1900 |

Weight(kg) |

550KG |

Product Performance

① Automated operation: automatic control,users only need to manually add bottles and bottom caps,the equipment automatically supplies botes/automatically quantitatively flls,automatically covers/automatically presses caps/automatically unloads materials, greatly improving production efficiency.

② Intelligent control: The whole machine adopts PLC controller and touch screen,strict precision control and processing technology of various transmission parts,the equipment is stable and responsive.

③ Accurate quantitative filing:volumetric metering cylinder is adopted,and servo motor controls quantitative.The filing metering accuracy is high (error 0.5%),and the metering parameters are adjusted by touching the screen.

④ Materialfiltration: material filtration function,standard filtration device.

⑤ Modular design:bottle unscrambler ----filling and capping machine ----cap unscrambler.

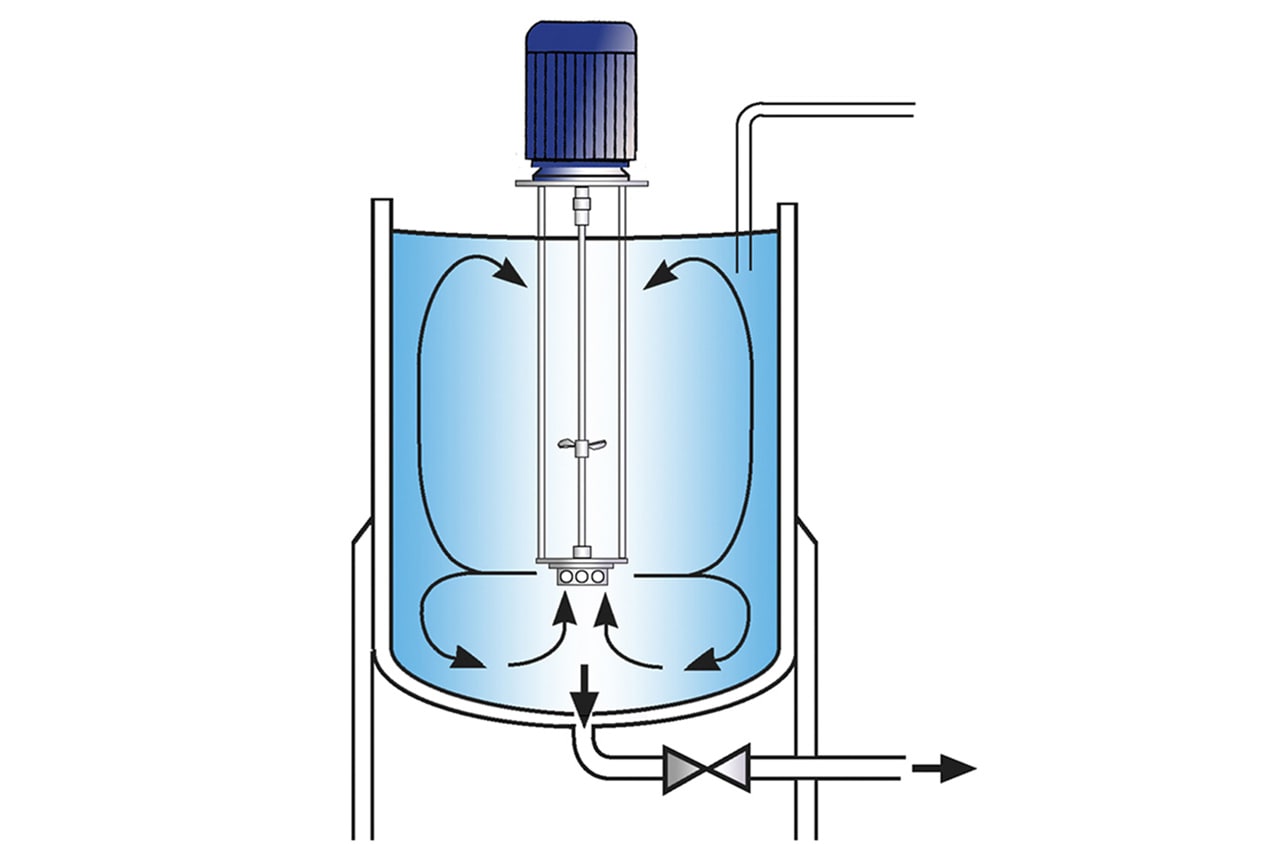

High Shear Batch Mixers

●Suitable for batch sizes up to 400 US Gallons

●Can be used on mobile floor stands

●Sealed units available to control solvent/dust emissions

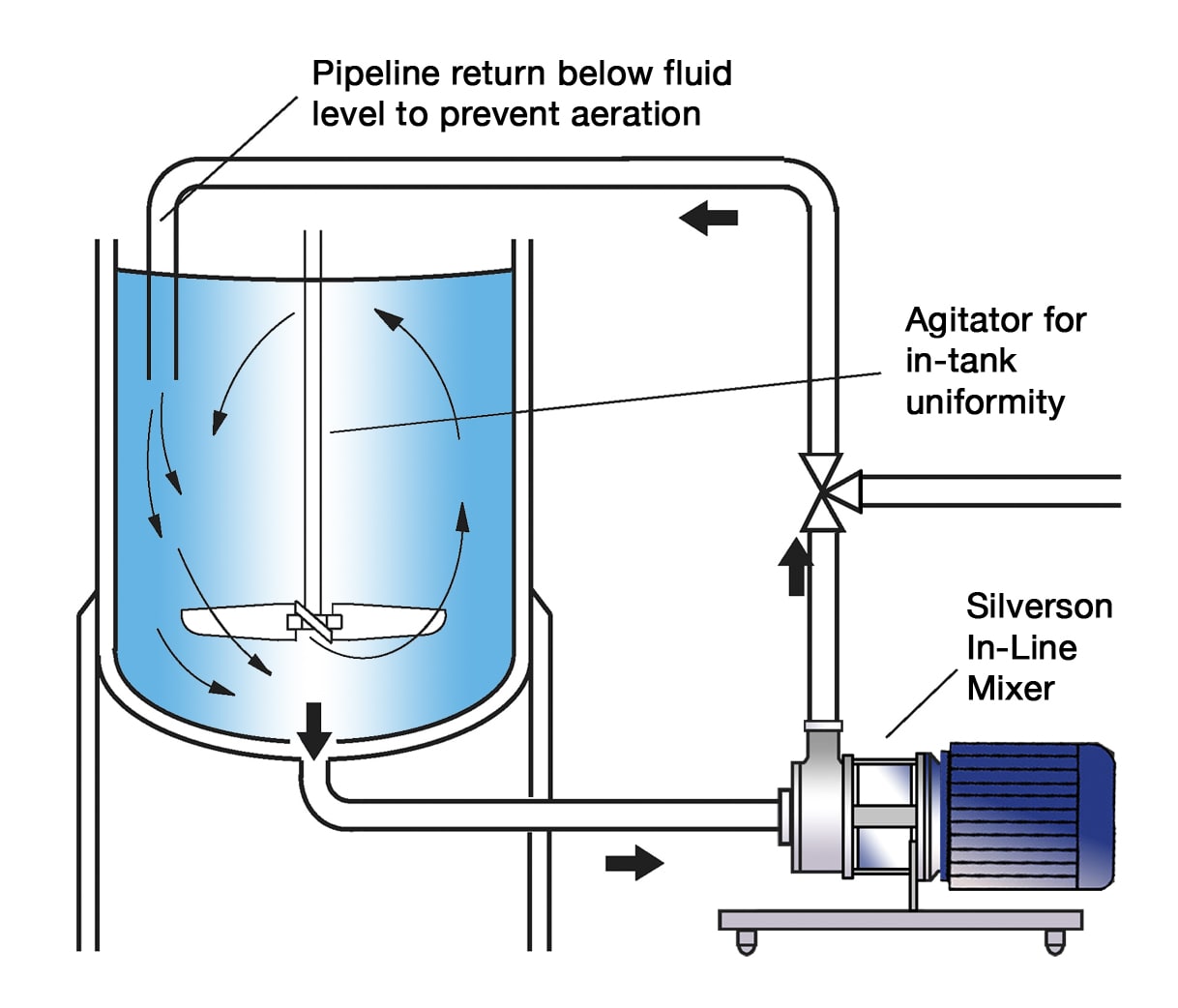

High Shear In-Line Mixers

●Ideal for larger batches

●Aeration free

●Easily retrofitted to existing plant

●Self-pumping

●Can be used to discharge vessel

●Multistage units available

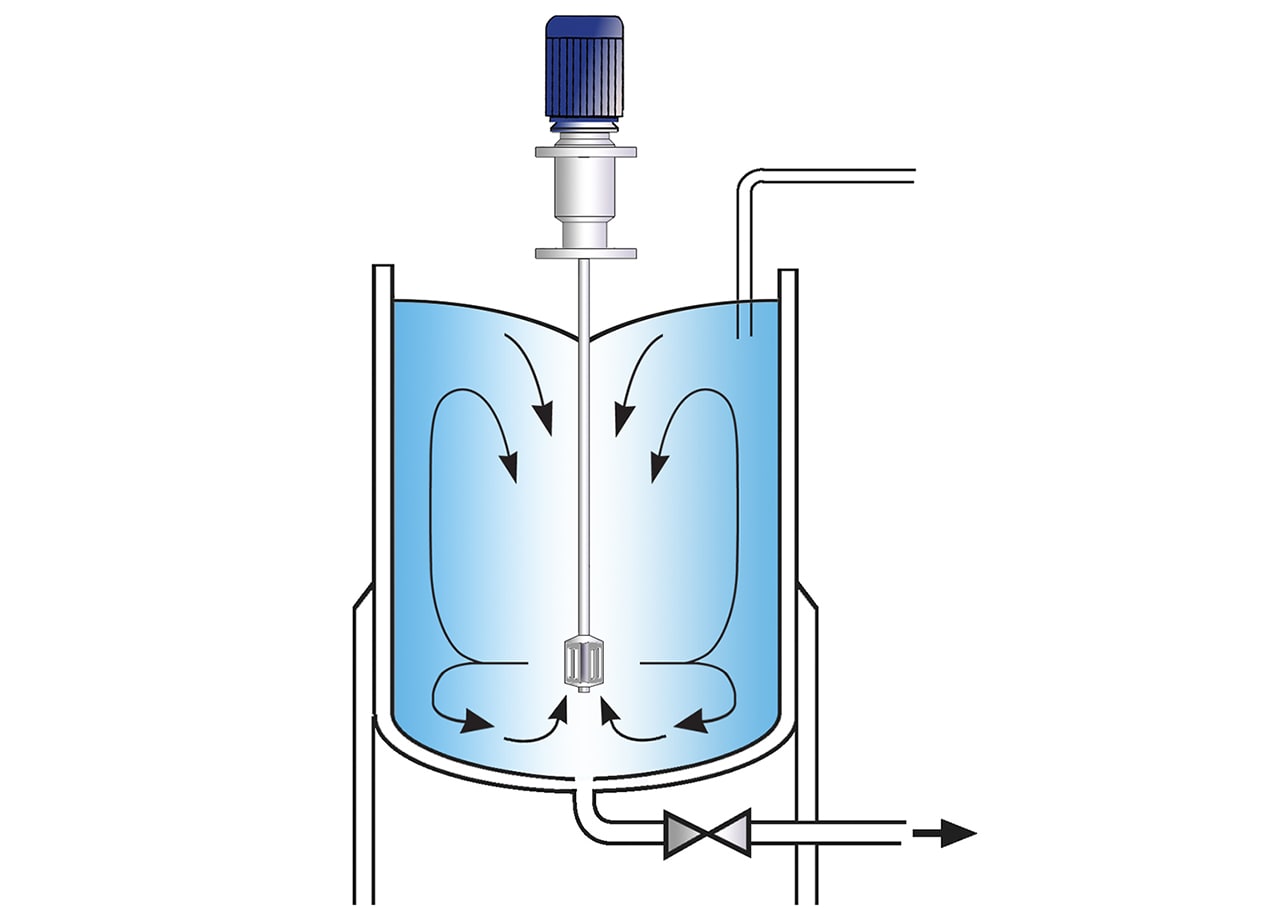

Silverson Ultramix

●Capable of rapidly incorporating large volumes of powders

●Excellent in-tank movement, even when processing high viscosity mixes

●The design is suitable for applications from aggressive chemical service to the most demanding sanitary standards and requirements

●Easy to clean - designed for Cleaning-In-Place

●Low maintenance - single-piece mixing head with no wearing parts or bushings

●Can be used in conjunction with a Silverson In-Line mixer where intense high shear is required

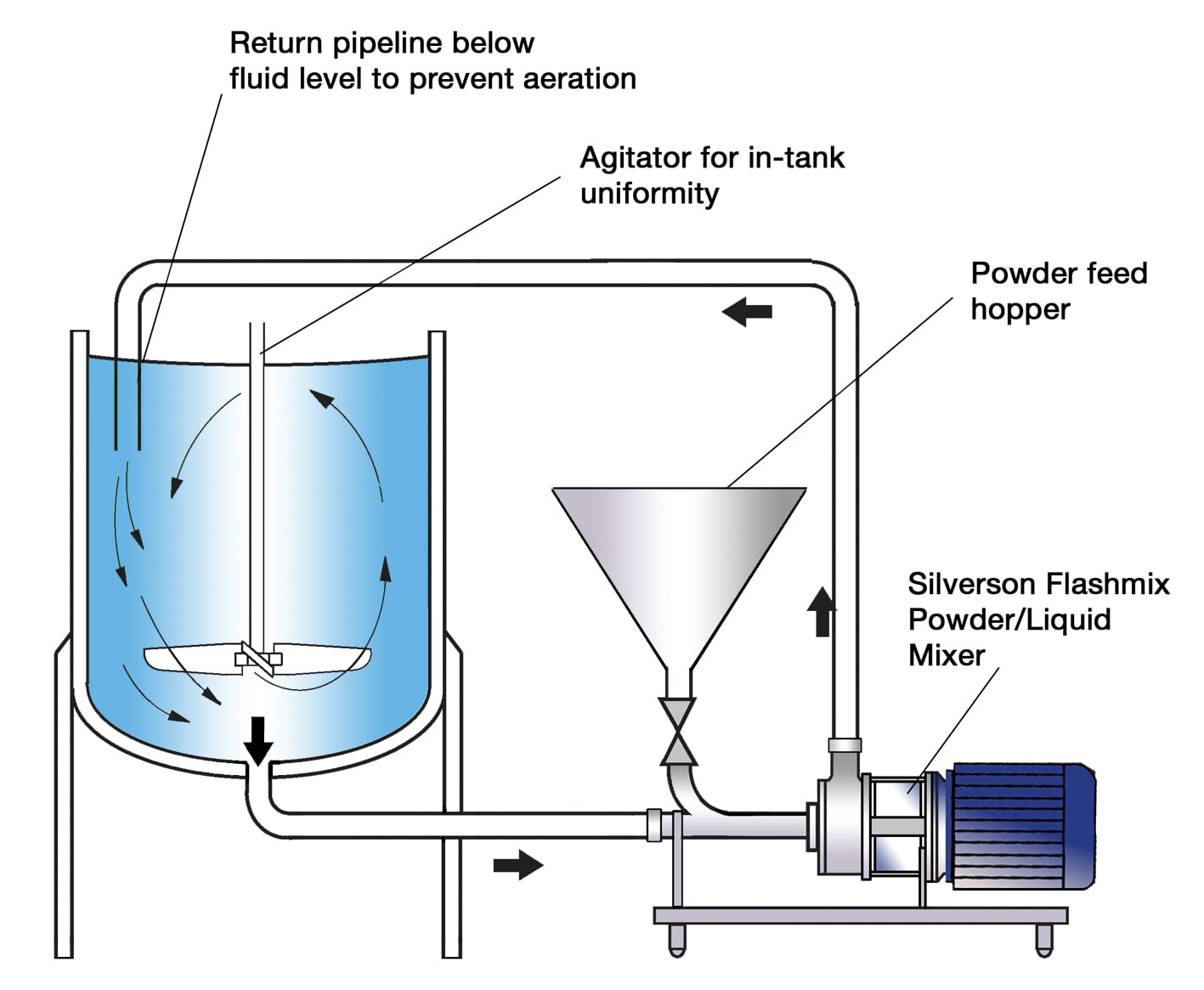

Silverson Flashmix

●Ideal for larger batches

●Capable of rapidly incorporating large volumes of powders

●Minimized aeration

●Minimized cleaning requirements

●Suitable for higher viscosity mixes

●Suitable for operation at higher temperatures

●Minimum operator input required

Related videos

the FXDJ planetary mixer from farfly for paint

1 minute sdf550 full introduction

Planetary mixer | operating instructions2

.png?x-oss-process=image/resize)